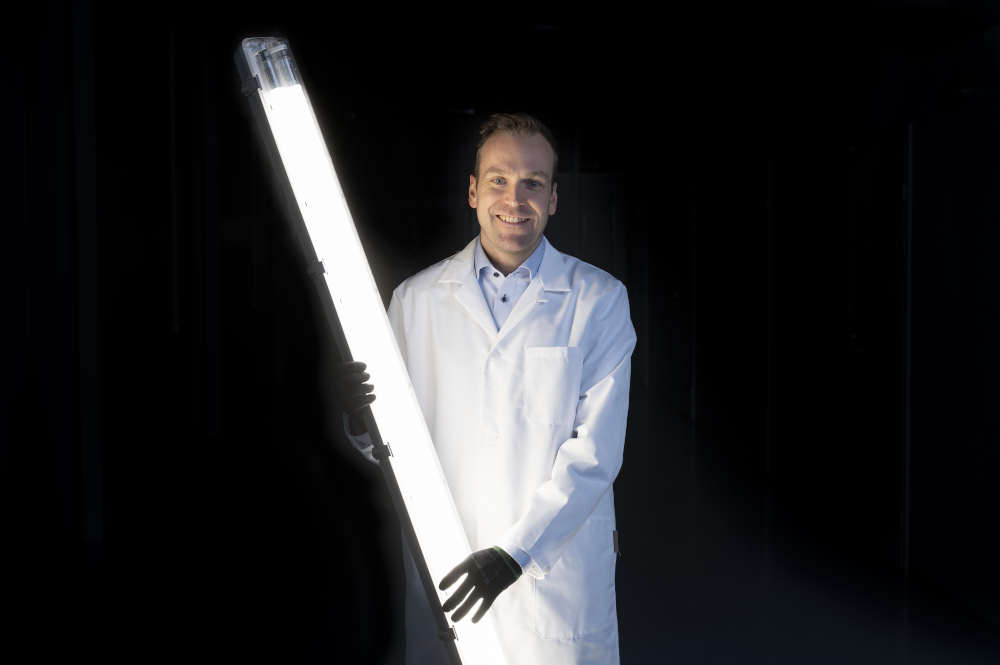

Lighting testing

Depending on the application, lamps, luminaires, and LED modules are exposed to different conditions, from the roof of the industrial hall to the open air, where rain and storms put a heavy strain on the lamp.

In Toptester’s services, you will find several test methods to ensure the quality of your product under different conditions.

Our services

Water- and dustproof tests

Water- and dustproof tests are the most common tests for lighting. We conduct such tests that are accredited to either IEC 60529 or IEC 60598. The IEC 60529 standard is a general standard of leakage testing for enclosure structures.

The IEC 60598 standard is a leak test standard specifically for lighting. The IEC 60598-standard tests generally follow the tests of the IEC 60529 standard, with the major exception that the electrical safety test follows the tests. We carry out the test required by the standard with the CE multi-tester.

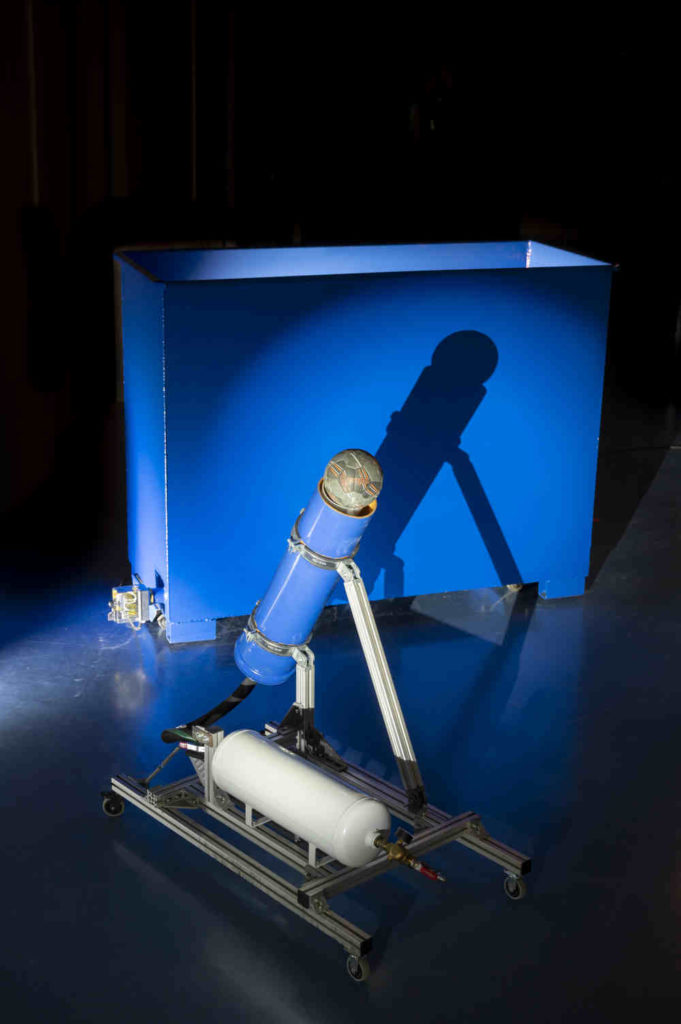

Ball cannon testing

To ensure ball-proof lights for a sports hall, for example, we carry out tests for lights that are going to be used in those conditions. The aim of this test is to ensure the function and mechanical durability of the lamp.

The test for this is regulated by the VDE 0710 Part 13 standard. In this test, the lamp is shot several times vertically and diagonally with a handball from a compressed air cannon. At the end of the test, the functionality and optical condition of the light are checked.

Wind and rain testing

If your product is outdoors and exposed to storms, for those conditions we offer a Wind Driven Rain test. The test is typically performed according to either the Telcordia or the MIL standard. During the test, the product is exposed to strong winds and rain from four or six directions.

At the end of the test, the functionality and optical condition of the light are checked. The lamp is also opened, and it is checked that no water has entered the lamp.

Vibration testing

For example, lamps may be in an environment that is exposed to vibration. This is the case, for example, with vehicles or bridges, where traffic causes constant vibrations. The Tira-shaker allows us to vibrate the lamp according to typical vibrations, for example in trains or vehicles. These tests are guided by several different standards. The vibration can also be performed based on the actual measured vibration data provided by the customer.

Temperature testing

During the temperature test, the function of the light is checked against the desired temperatures. Typically, temperature and humidity tests are governed by the IEC 60068 series of standards. In this test we use temperature cabinets, aka climatic chambers to create the desired temperature.

With this test, the functionality of the lamp can be verified under the following conditions, for example temperature + 40˚C and humidity 93% or another example of cold: temperature -40˚C and holding time 24 hours.

Impact testing

The degree of impact resistance of the light can be verified by an official, accredited IK impact tests. Impact tests are regulated by the SFS-EN 62262 standard. In this test, an impact element according to the requested IK class is dropped onto the lamp in a controlled manner.

The standard also allows the use of a pendulum hammer for this test, and you will also find this test device in our range.

Contact us: info@toptester.fi

kari.valikangas@toptester.fi

+358 40 653 8005